We are dedicating passion and great investments in human resources for staying updated with latest technologies, for researching and developing innovative material for improving quality and performances of our products.

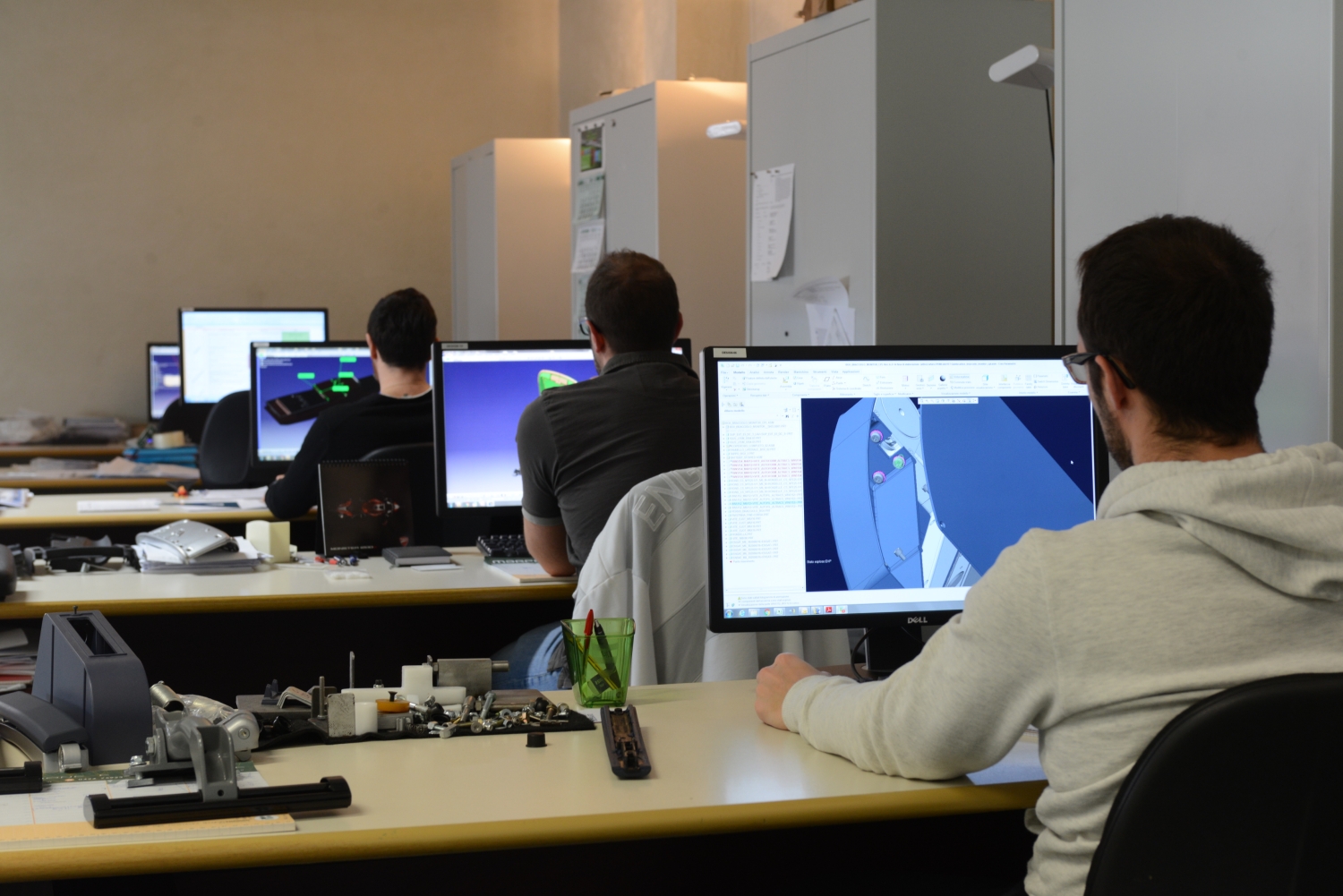

Our teams of dedicated researchers, technicians and engineers can rely on the latest 3D modeling and simulation software currently in use in both the Railway and Automotive industry and on a highly specialized prototyping and testing department for verifying and optimizing product performances.

HOW WE PROCEED

DESIGN

We rely on partnerships with major Universities and design studios to improve technical performances, safety, comfort, functionality, and style for granting innovative solutions

3D PRINTING

We are equipped with highly specialized 3D printers for rapid prototyping all kind of parts ranging from plastics to metals, for mock-up phases and small serial production

SIMULATION

We verify the resistance and safety compliance of our Products at an early stage of designing before manufacturing serial tools by means of structural simulation software such as ANSYS

PATENTS

We are committed to develop customer specific solutions and to patent them in case of unicity for protecting our intellectual property

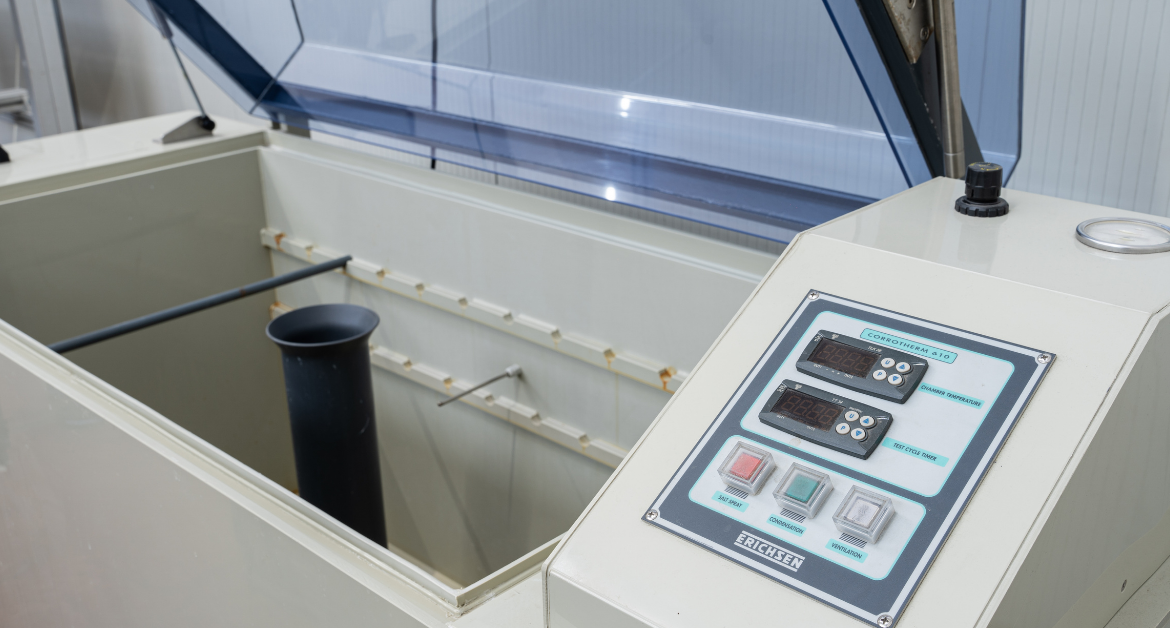

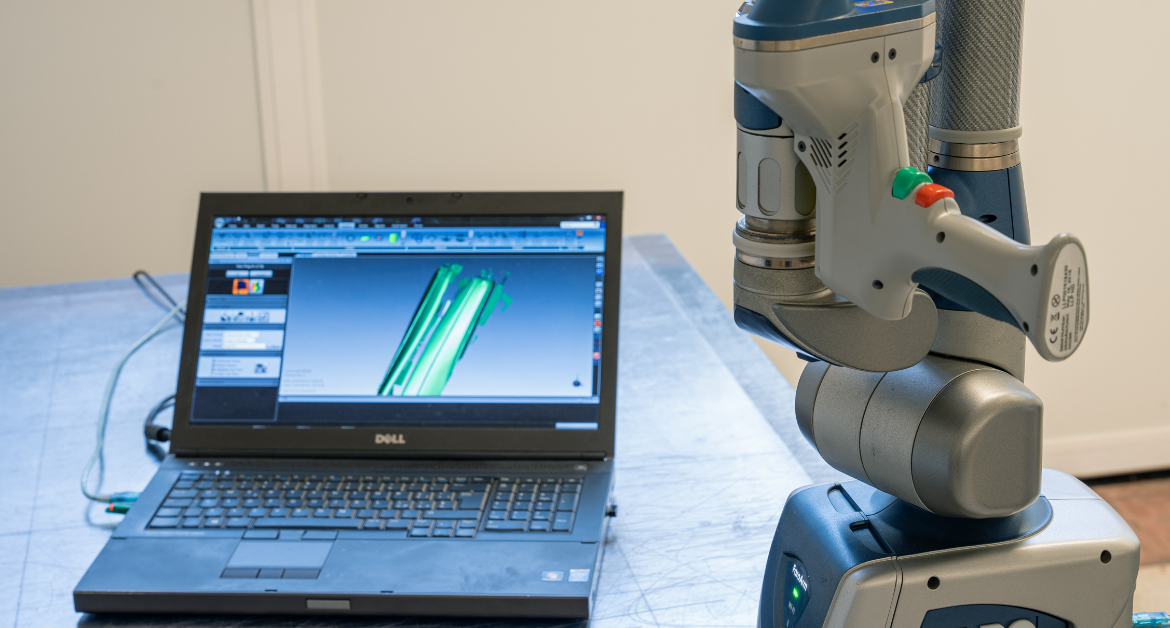

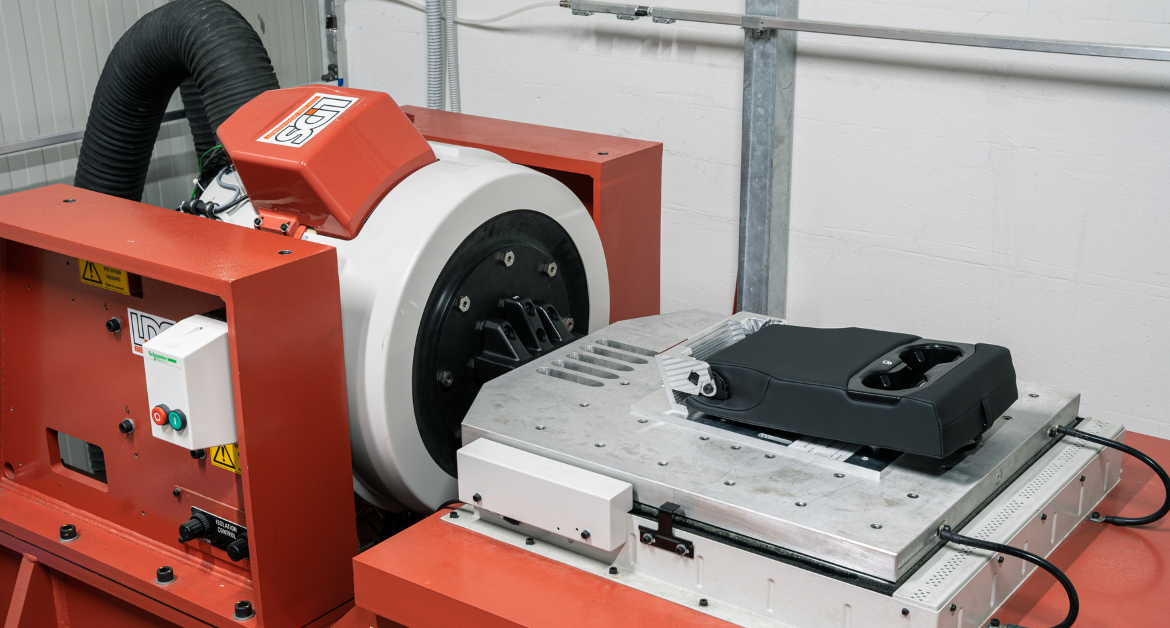

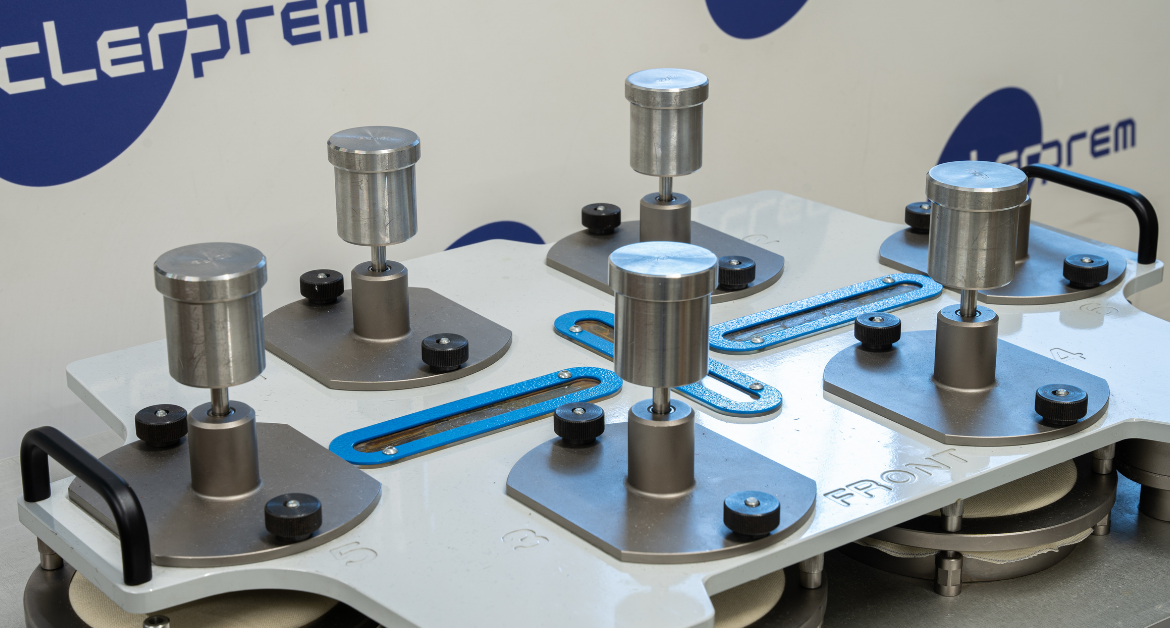

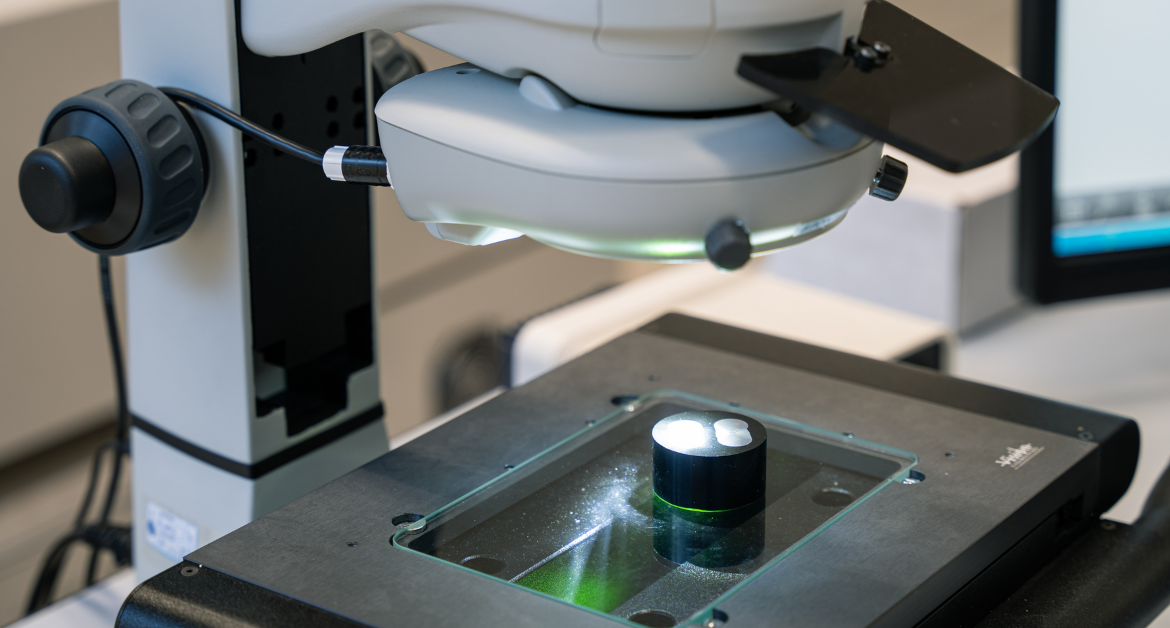

testing LABORATORY

We are equipped with an internal laboratory in order to perform in-house testing on materials, components and finished products to verify their compliance with requirements.

We constantly research and develop our products, thus ensuring the high-quality levels required by customers, counting on modern testing equipment and qualified staff.

cmm dimensional inspection

STATIC TEST

AIRBAG TESTING

FATIGUE/CYCLIC TEST

corrosion test

laser scanner dimensional inspection

VIBRATION test

abrasion TEST

universal testing machine

comfort test

cyclic/fatigue test

microscope projector metrology inspection

We are proudly presenting our first branded product: Future First armrest.

This project was developed by our internal team of engineers in collaboration with Michelangelo Design Institute, located in Bologna.

The armrest style was conceived by young designers in order to satisfy the increasing technological demand of this era: a wireless charger and our innovative solution for the Multi Media Interface are integrated directly in the armrest pad instead into the console for an optimal ergonomics.